The Intel 4004 after 44 years! 2015 Progress Report

A new foundation for the future: making the inner workings of the microprocessor accessible to students young and old

Team leader Tim McNerney's original goal for starting this project was to make the invisible machinery of the first computers-on-a-chip visible and understandable to students and the lay public. The 4004 is great for many reasons, but for this project it's number one selling point is that it is a minimal CPU. This is extremely useful for teaching purposes. In the coming months before the 45th anniversary, we will be working to make the 4004 and fundamentals of computers and digital logic even more accessible though the confluence of art, education, and technology. This project could never have been done alone. It needed an international team of volunteers.

New: Scalable Vector Mask Artwork for Museum-sized Exhibits

For years, our project made do with mask artwork scanned from an Intel Archives' set of aging mask proof transparencies. These were invaluable for making silkscreens for the Intel Museum exhibit's 16x23 inch "big chip" 4004 replica still on display. Later, with some bitmap scaling, alignment, and careful corrections, thanks to Lajos Kintli, we succeeded in verifying them against Fred Huettig's paintstakingly re-captured schematics.

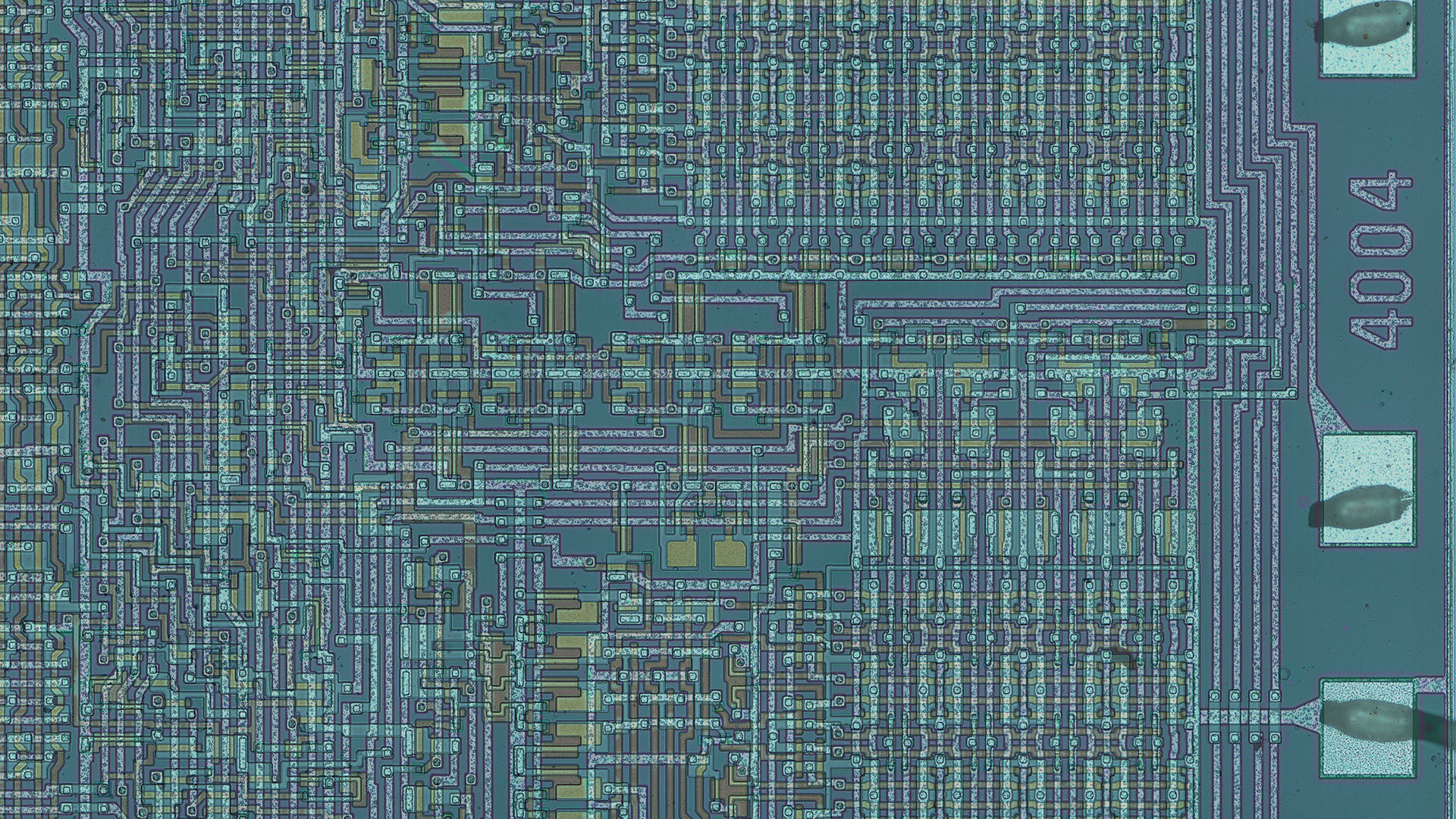

If you look too closely, the old proof set artwork is pretty ugly, certainly nothing we could use if we wanted to build a larger museum exhibit, say 3x4 feet, or import the mask artwork into a PCB layout package to build a giant, working circuit board. The old artwork just wasn't going to cut it. So McNerney took a pair of high-resolution photomicrographs (kindly donated by reverse engineer extraordinaire, Christopher Tarnovski), and set out to trace every wire, transistor, resistor, and capacitor using Adobe Illustrator. Just hours before the 44th anniversary, he finished tracing the first, complete draft of the mask set artwork.

The next step is to verify the mask artwork against the schematics and try it out in simulation. Right after the announcement we found a few inevitable omissions (mostly missing vias), using the "eyeball method," which is what Federico Faggin and Masatoshi Shima had to do in 1970 (remember, t'was all "analog" back in the day... see below). Lajos has just begun to apply his software analyzer/verifier to compare the new artwork against Fred's schematics, and he has some obstacles to overcome due to the misalignment of the polysilicon layer that occured back when our photographed sample chip was fabricated.

We hope and pray that Intel's lawyers will give us their blessing to release these high-quality 4004 mask reproductions (even though we can only make educated guesses on original dimensions, spacing, and design rules). Optimistically assuming that happens, our intention is to release the new mask artwork sometime in 2016, probably for non-commercial use only. The license that Intel routinely grants for 4004 assets is very similar to the Creative Commons BY-NC-SA license that we use on this web site. As entrepreneurs know so well, "past performance does not guarantee future results," so we need to remain patiently enthusiastic.

The complete chip: A composite of the mask artwork—six layers in all: metal, polysilicon, diffusion, vias, buried contacts, and passivation.

Detail of the DRAM decoders and "4004" label.

Celebrating the unsung artists of Silicon Valley: Rubylith cutters

Back in the early 1970s, CAD software for chip design was rarely found outside of large corporations, if at all, design-rule checkers were people, and Adobe was still just the name of the little creekbed that ran through my back yard in Los Altos, California. For MSI (Medium Scale Integration < 4,000 transistors) mask "artwork" was hand-crafted on giant light tables by "rubylith cutters." Semiconductor engineers like Federico Faggin would draw parts of the layout on paper, trying to squeeze as much digital logic into a 3x4 millimeter rectange of silicon as they could. The rubylith cutters turned engineering sketches into the carefully aligned, lithographic masks that would be photo-reduced and used to fabricate (mass produce) the actual semiconductor chips.

If you know any of these unsung heros, or were one yourself, please contact us. We'd love to hear your stories.

(Photo courtesy of Intel, originally published on the Computer History Museum web site but now only still available thanks to Brewster Kahle's Internet Archive)

This is is an "X-ray" composite of two photomicrographs we used to re-create the mask artwork: one with metal stripped away, exposing the partially hidden polysilicon, diffusion, and buried contact layers. The original, unstripped die photo, is "ghost" superimposed, making the metal layer appear see-through, while still revealing the underlying detail.

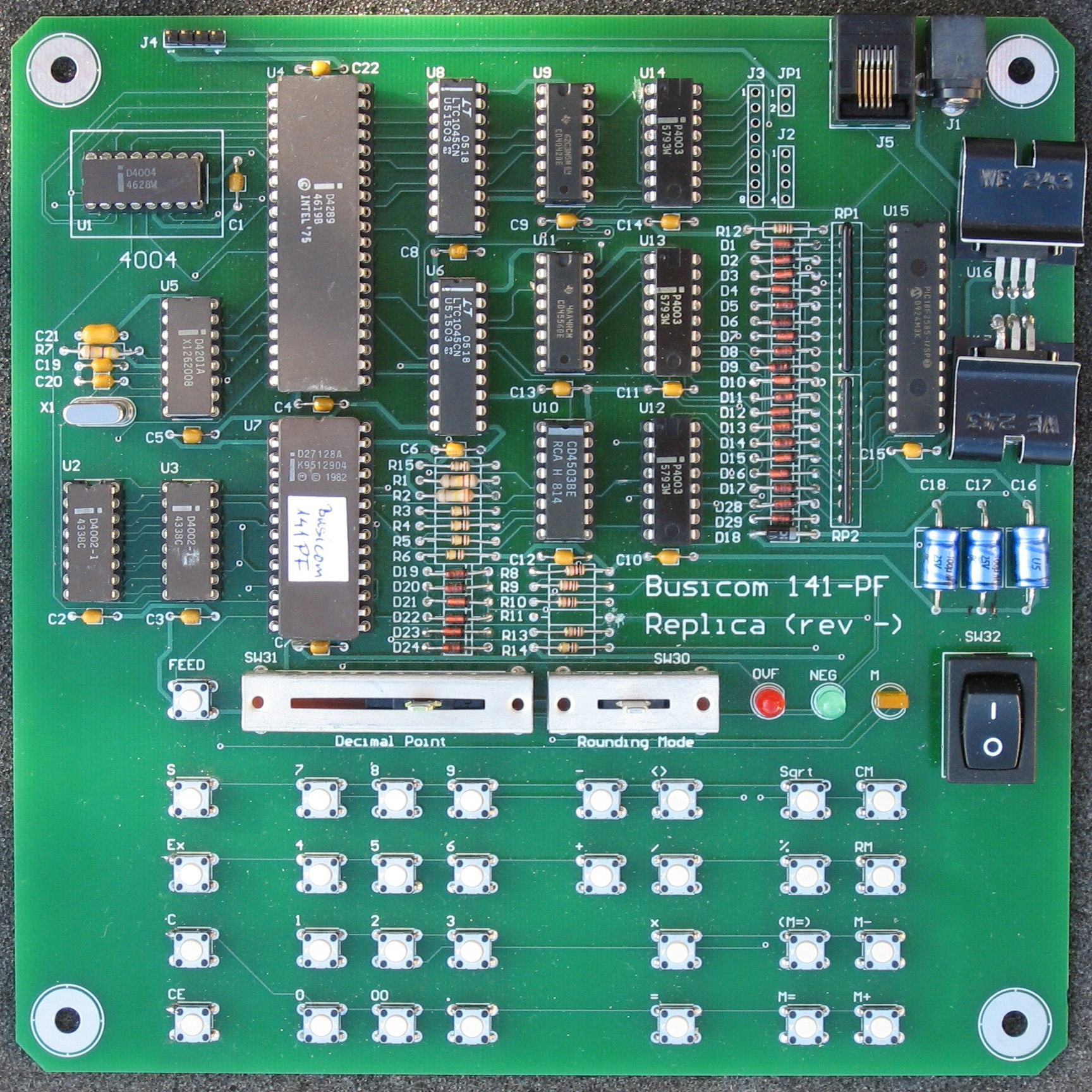

Revision 2 of the 2010 Busicom 141-PF replica PCB

Bill Kotaska "beat us to the punch" with the replica he built in 2008, complete with a printer salvaged from another vintage calculator. But still, in 2010, we wanted to make a PCB based replica of our own using vintage chips: the original 4002s, 4003s, and 4004, plus a 4201 clock generator, and a 4289 memory interface (so we could use an old EPROM to replace the impossible-to-find, custom-programmed 4001s with the Busicom firmware... yes, not even on eBay). Now we are working on Revision 2, with corrections and improvements.

Here is the first version that I designed, fabricated, and assembled. Not quite working before my visit to Hungary in 2010, I still I brought the prototype to Lajos Kintli as a gift, and after a little PCB surgery and new printer emulator firmware, he brought it to life (see printer output below).

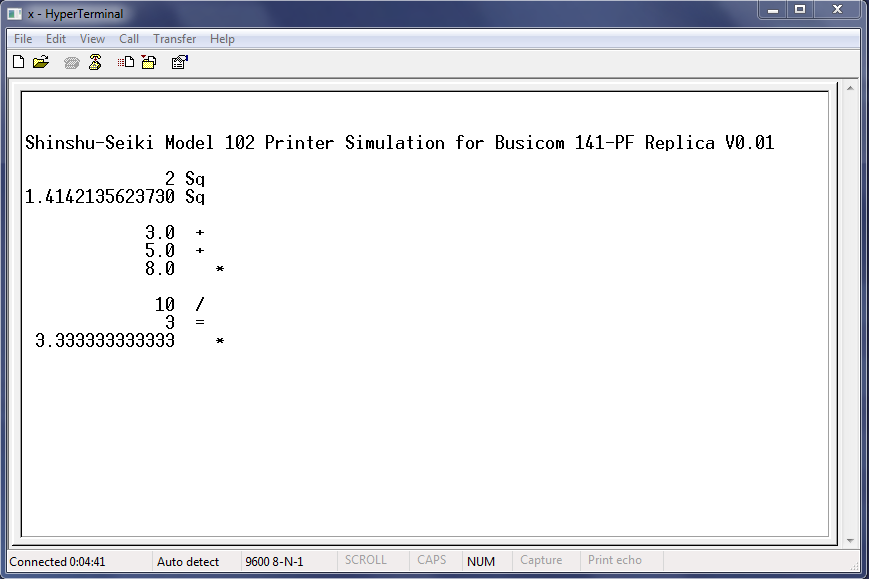

Shinshu-Seiki Model 102 printer emulator code

Lajos Kintli's printer emulator for the PIC18F2585 converts the hammer signals to serial. This lets you view printer output from the replica on a PC terminal window (as shown below) or on real hardware using a small LCD panel with a serial input. The printer emulator is also important simply to make the Busicom calculator software work at all, by providing a "heartbeat" signal that was generated by the spinning printer drum in the original.

Credits

- Fred Huettig, schematic capture, museum electronics, FPGA design

- Lajos Kintli, verification software, reverse engineering: software, 4001

- Christopher Tarnovski, high-resolution die photographs of 4004

- Brian Silverman, simulation software, disassembler, strategy

- Barry Silverman, simulation software

- Tom Knight, die photographs of 4001

- Federico Faggin, in many ways, including 4001 prototypes

- Computer History Museum, contents of 4001 Busicom ROMs

- Tracey Mazur, Intel, funding, located 4004 schematics, mask proofs

Legal Notices

- The software (e.g. simulators) and engineering documents (e.g. schematics, drawings, etc.) are provided "AS IS" with no warranty expressed or implied. Fitness for any particular purpose is not guaranteed. The authors do not accept any liability for use of this information.

- The works on this web site are licensed under a Creative Commons Attribution-Noncommercial-Share Alike 2.5 License.